As Torpido Makina, we are recognized for our advanced engineering solutions for the maritime and industrial sectors. We have once again demonstrated our expertise in this field with a comprehensive generator conversion project carried out for a customer in Italy. This case study details the technical and strategic aspects of upgrading older generation generator systems to comply with the latest IMO III emission standards.

Strategic Rationale and Scope of the Project

Today, the maritime industry is not only the lifeblood of global trade but also at the center of increasingly stringent environmental regulations. Emission regulations set by the International Maritime Organization (IMO), particularly IMO III standards, mandate a significant reduction in nitrogen oxide (NOx) emissions. These regulations directly affect operational processes such as port entry and sailing in specific emission control areas. The older generator sets in our customer's fleet were falling short of these standards and limiting the ship's operational flexibility in international waters.

In this context, Torpido Makina developed a turnkey project covering the entire process, from the dismantling of the existing generators to the installation of new and modern sets. The main objective of the project was to modernize the ship's power system, ensuring full compliance with international regulations and maximizing operational performance. The project was approached holistically, going beyond a simple engine replacement to include system integration, engineering calculations, and international certification processes.

Technical Application and Engineering Details

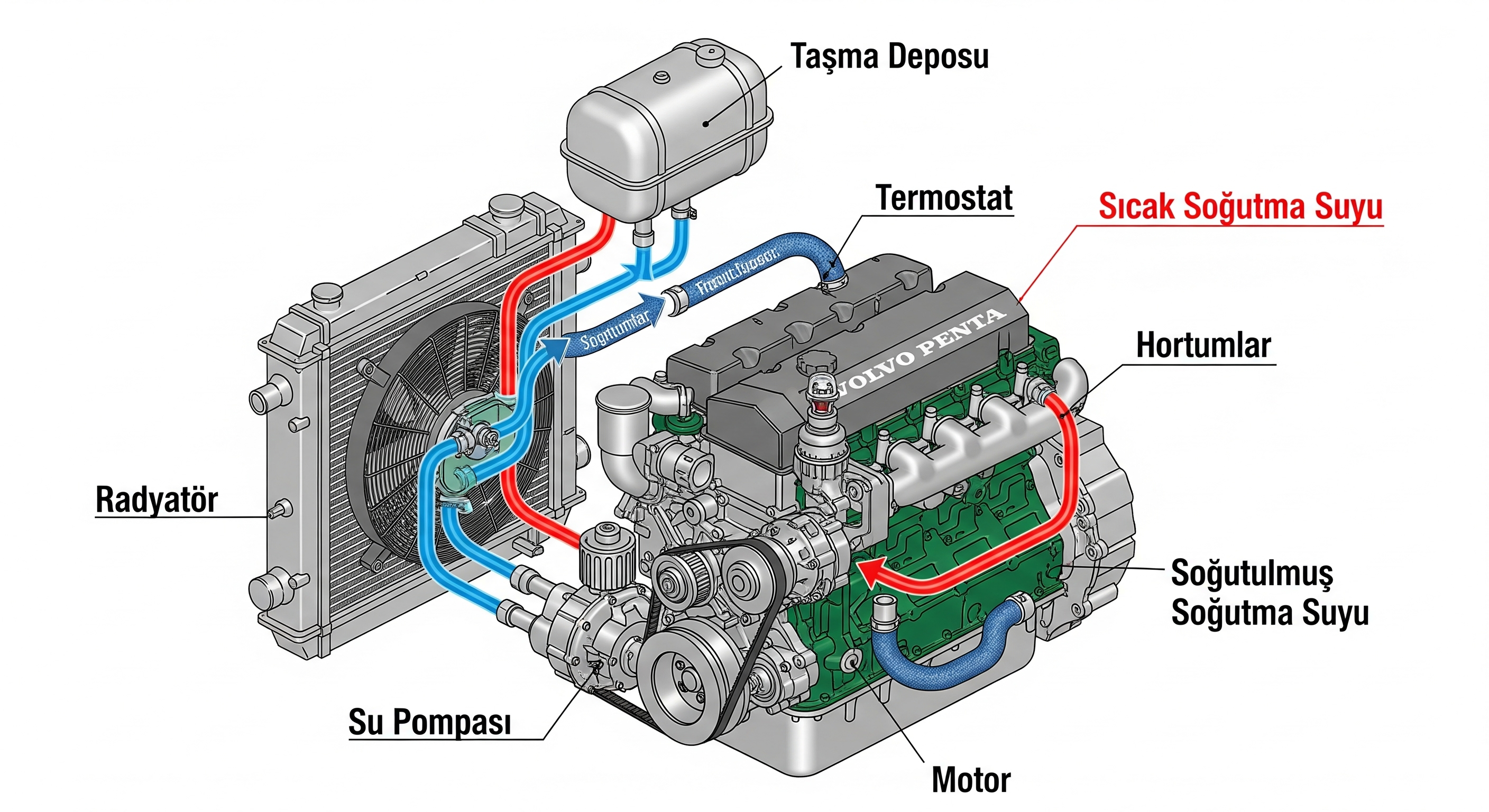

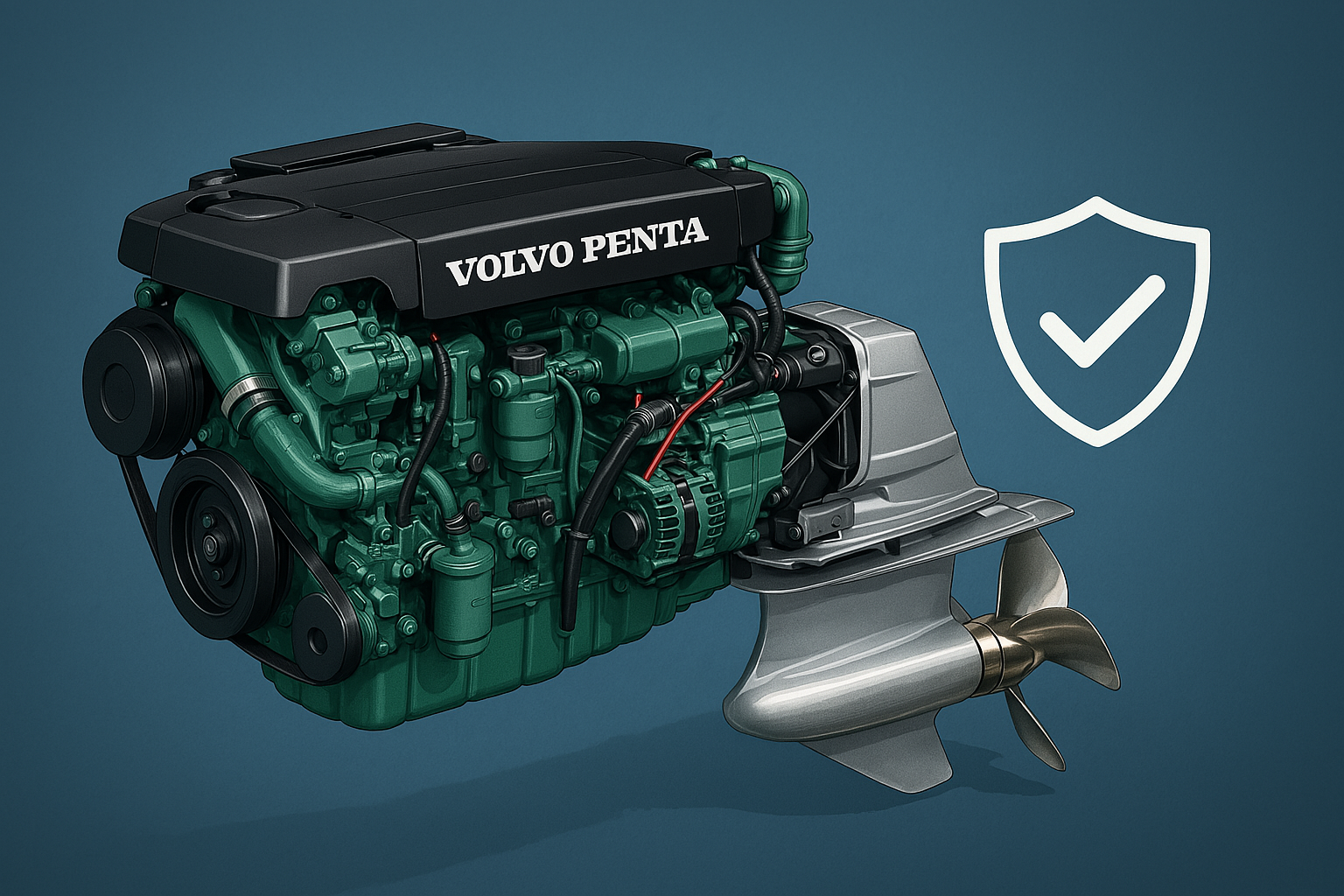

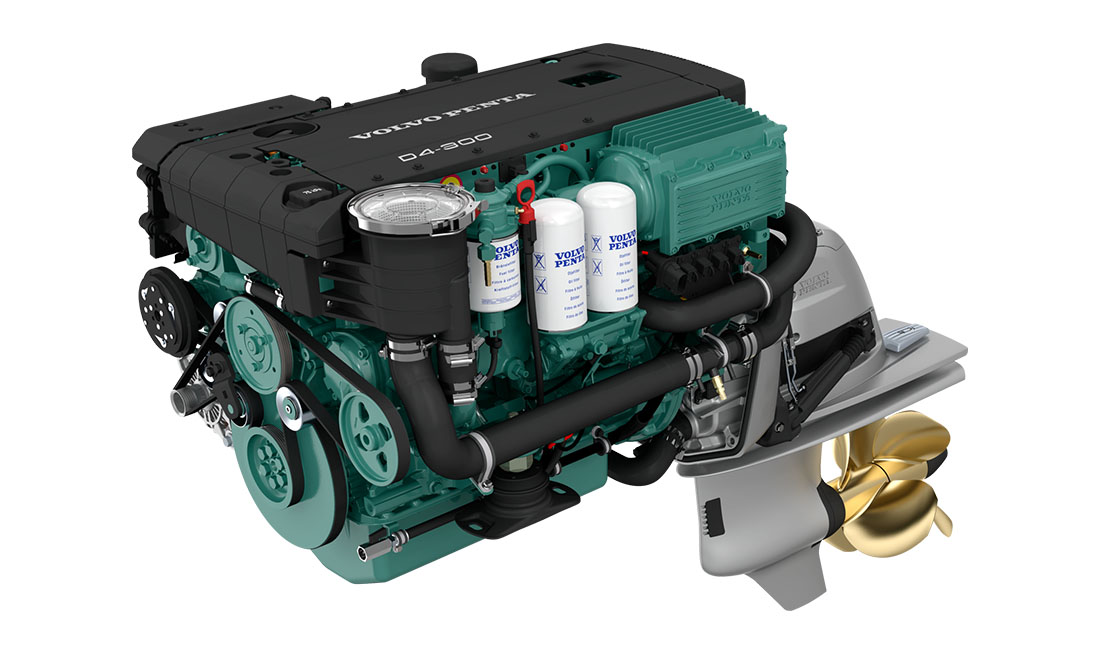

At the heart of the project, high-efficiency Volvo Penta D16 MG IMO III generator sets, each producing 585 kW of power, were installed. These sets can meet even the most stringent environmental standards thanks to advanced exhaust gas treatment and combustion control technologies. The project process consisted of meticulously managed steps requiring high precision:

Integration of New Generators: Volvo Penta D16 MG sets were installed in the spaces vacated by the old generators, in accordance with precise engineering drawings. At this stage, the engines were properly secured to the chassis, vibration damping mounting elements were used, and all mechanical connections were checked for compliance with standards.

Integration of New Generators: Volvo Penta D16 MG sets were installed in the spaces vacated by the old generators, in accordance with precise engineering drawings. During this phase, the engines were properly secured to the chassis, vibration damping mounting elements were used, and all mechanical connections were checked for compliance with standards.

Electrical Synchronization and Integration: Electrical integration, one of the most critical stages of the installation, involved seamlessly synchronizing the new generators with the ship's main power distribution board and other generators. Our expert team successfully completed complex tests to optimize load sharing, ensuring the system's safe and efficient operation.

Classification and Performance Approvals: The project was completed under the supervision of international classification societies (such as DNV, ABS, RINA). Comprehensive static and dynamic tests documented that the generators met the specified standards for performance, fuel consumption, vibration, and emissions. These official approvals are vital for the ship's international operations.

Project Management and Process Optimization

The success of this project stems not only from our technical capabilities but also from the meticulous management process we implemented from start to finish. Our project management team closely monitored all stages, identified potential risks in advance, and optimized the process with solution-oriented approaches. This approach enabled us to achieve the highest quality results while adhering to the project's budget and time targets. Our continuous communication with our customer and transparent reporting process created an environment of complete trust and cooperation at every stage of the project.

This detailed and comprehensive modernization project once again highlights Torpido Makina's competence in complex engineering projects and its customer-focused solution approach.