The Volvo Penta D8 engine training course organized for Coast Guard, Customs Enforcement, and General Directorate of Security personnel was successfully completed. The four-day training program aimed to deepen participants' technical knowledge of Volvo Penta engines and develop their practical application skills. This comprehensive training, which included both theoretical and practical sections, provided participants with important insights into how to deal with technical problems they may encounter in the field.

Day 1: Theoretical Training

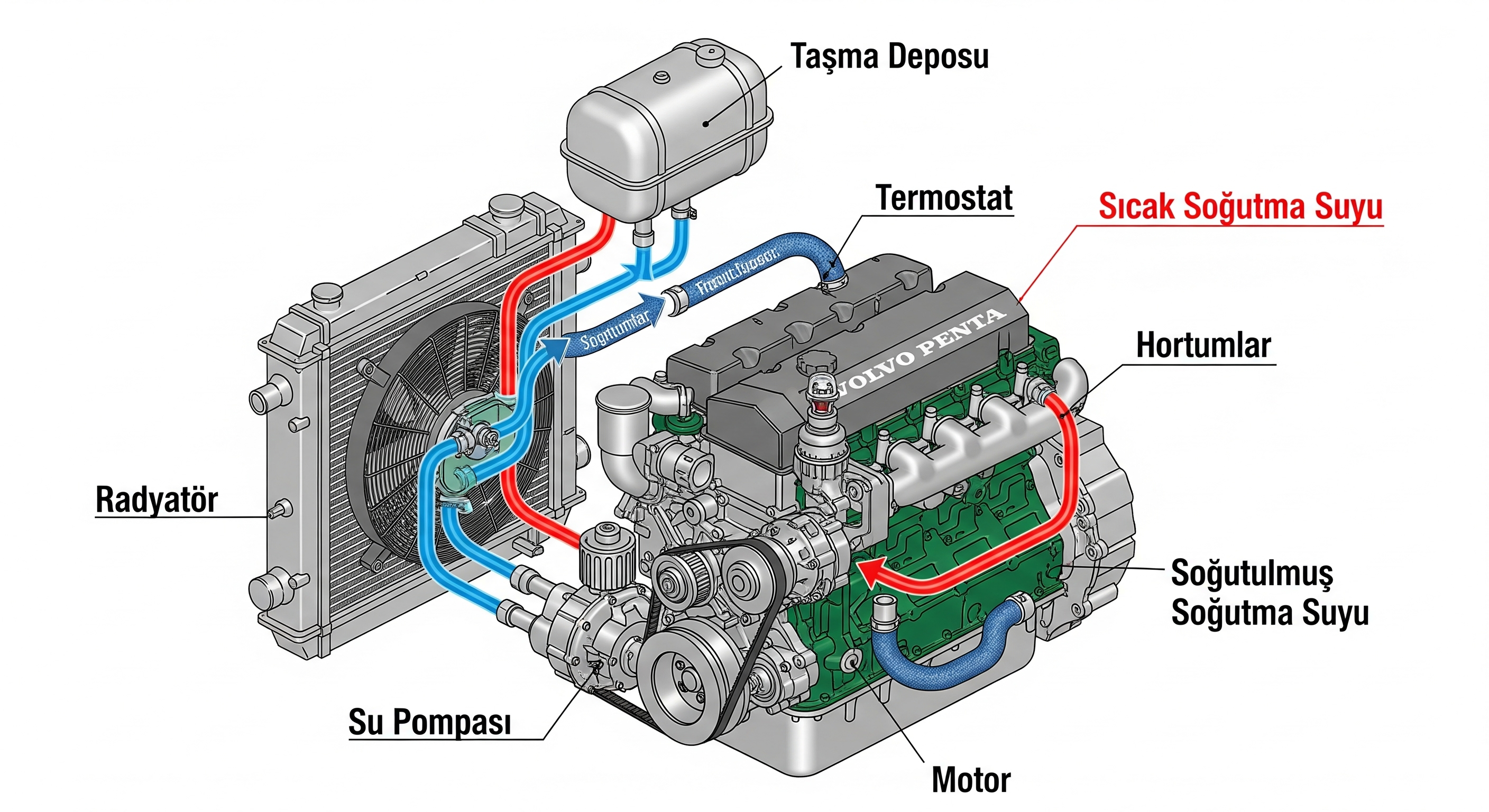

On the first day of the training, the theoretical information about the Volvo Penta D8 engine was covered. Participants received detailed training on the operating principles of the engine, its technical specifications, and innovative technologies that increase the engine's efficiency. This theoretical training covered critical topics such as how to operate the engine more efficiently, how to optimize maintenance processes, and what to pay attention to in order to maximize engine performance.

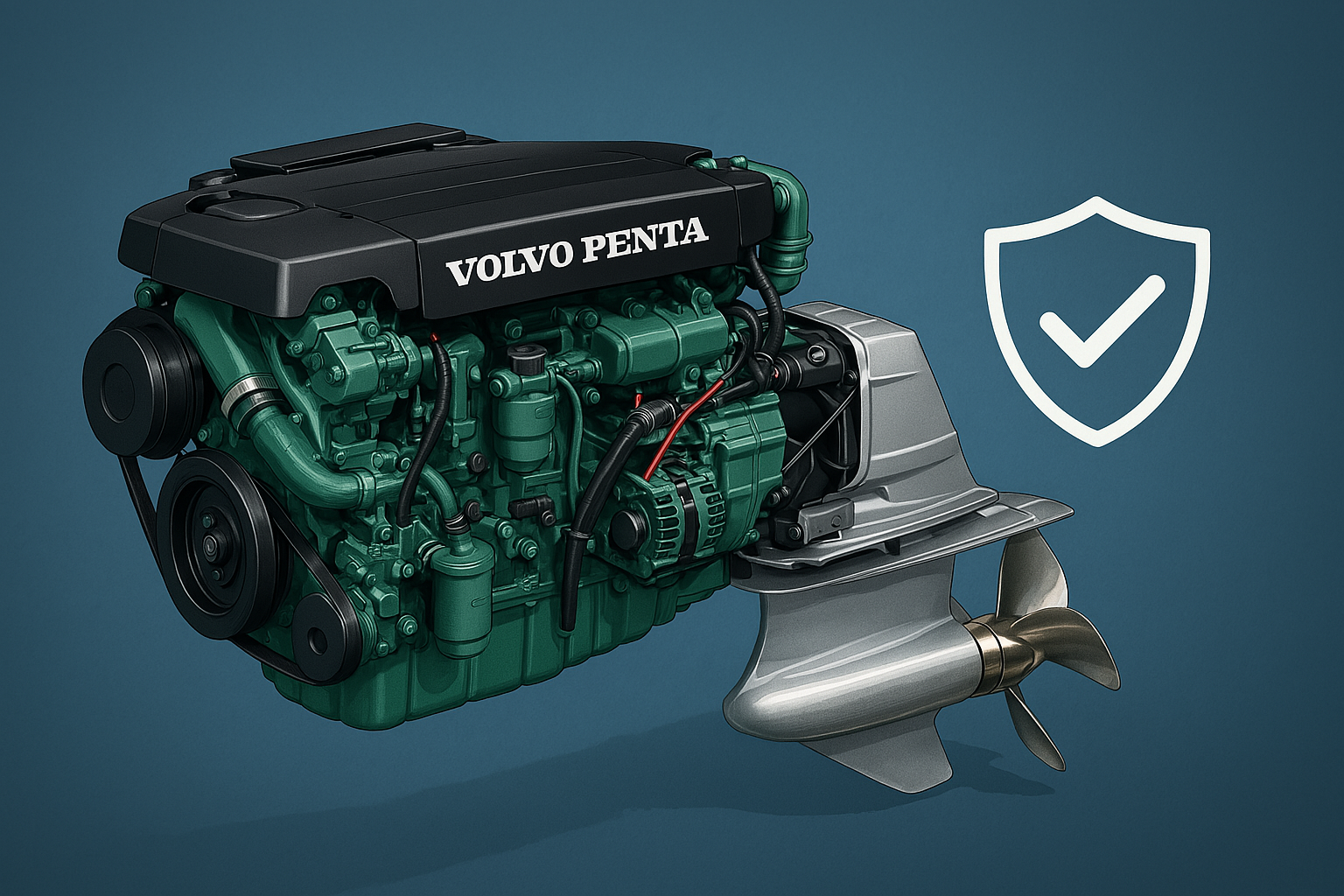

Our instructors emphasized the Volvo Penta D8 engine's position and reliability in the marine industry, while giving participants the opportunity to ask technical questions about the engine. This stage was of great importance in terms of understanding the engine's operating structure and laying the foundation for future practical applications.

Day 2: Practical Training – Disassembly Process

On the second day of the training, participants moved on to practical applications of the Volvo Penta D8 engine. Under the guidance of instructors, the engine parts were disassembled, and more detailed information about the internal structure of the engine was shared. Participants had the opportunity to learn about the main components of the engine up close and how the parts are carefully disassembled. This practical training provided an opportunity to experience firsthand the challenges that may be encountered, particularly in maintenance and repair processes..

During the disassembly process, detailed explanations were provided on how each component of the engine works and how the proper functioning of these components affects engine performance. As a result, participants gained the knowledge and skills to respond more quickly and effectively to maintenance and repair needs they may encounter in the field.

Day 3: Practical Training – Collection Process

On the third day, hands-on training was organized for participants to reassemble the engine. All parts of the Volvo Penta D8 engine were assembled by participants based on the knowledge they had acquired during the disassembly phase. This process was of great importance in terms of allowing participants to put their theoretical knowledge into practice and gain a deeper understanding of how the engine works.

The trainers emphasized the points to be considered during assembly and guided the participants through the process of reassembling the engine. Thanks to this training, the participants consolidated their knowledge of the internal structure of the engine and gained comprehensive experience of how it works. They also learned how to perform such technical operations quickly and accurately.

Day 4: General Information About Volvo Penta Systems

On the last day of the training, information was provided about the general systems of Volvo Penta engines. Participants received detailed information about systems that increase engine efficiency, fuel-saving technologies, and innovations that improve overall engine performance. In addition, Volvo Penta's other marine engine systems and the advantages of using these systems were discussed.

This general briefing enabled participants to evaluate their knowledge of engines from a broader perspective. The effectiveness of Volvo Penta's superior technology and reliable construction in field applications was explained. Participants expanded their technical knowledge by learning how engines can deliver the best results in different areas of use.